Metal hose installation should follow a proper guideline to ensure its optimum lifetime performance and minimize risk to workers and equipment. This blog aims to highlight some necessary steps that aids in maximising your hose life, especially in metal hoses.

1. Proper Hose Length

Metal hose assembly should have more length than its port to port distance as hose can elongate and contract when pressurized. The contraction will add more stress to the assembly and might lead to catastrophic failure such as leak, loose fitting and hose failure. In addition, having too much length will also give adverse effect as it might introduce new problems such as hose abrasion and uncontrolled hose movements.

2. Proper Placement

Proper placement can prolong metal hose life significantly. Below are the correct ways to place your hose:

1. Avoid Stacking – Avoid adding extra load such as valve or piping onto your hose as it might crush the hose underneath.

2. Store it Safely – Make sure your hose is installed away from potential risk and hazards that can damage the hose (e.g heat, chemical or corrosion).

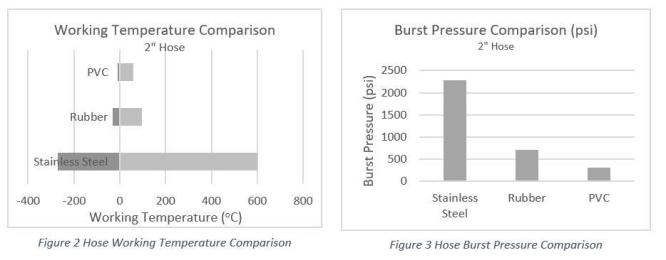

3. Protection Against Extreme Temperature Change

Extreme temperature can cause tears and cracks to your hose. Avoid direct contact between the hose and heat source or use additional protection such as protective sleeves to protect your hose.

4. Avoid Torque

When your metal hose is torqued/twisted, it has a higher chance of failure as hose is not designed to withstand torsional force. During installation, use swivel fitting on one end and fixed end on the other end and always make sure the assembly has only one plane of flexing to avoid torsional stress. In addition, proper tightening will eliminate torque movement during the hose operation.

5. Avoid Over or Sharp Bending

Bending metal hose into a radius smaller than its Minimum Bending Radius (MBR) could result in hose failure. Provide enough length, use elbow/pipe bend to avoid sharp bend and use support such as a suspension to avoid hose sagging. Check bending radius on datasheet before installing.

6. Avoid Abrasion

Hose abrasion occurs because of constant contact between hose and abrasive surface. It can lead to hose failure as it gradually weakens the hose’s pressure retention. Introduce external protective cover such as spring guard, metal guard, etc to help minimize the friction or avoid dragging the hose on a rough surface to avoid abrasion.

7. Avoid Axial Overextension and Compression

Hose should not be stretched or compressed along its longitudinal axis. Axial overextension and over compression will damage the hose as it is not designed for in-line axial movement. Add a support to properly guide the hose routing or install the hose perpendicular to the direction of the movement.

8. Proper Grounding

Some fluid may contain solid impurities that if it is constantly rubbing the hose, it will create an electric charge on the hose surface. Establish a proper grounding route to prevent electrical discharge to the workers or equipment in near proximity of the hose.

9. Maintain Hose Cleanliness

Impurities such as debris, dust, rust and abrasive particles will accumulate during assembly step and after usage. The impurities can lead to serious wear and tear damage to the Stainless-Steel hose; therefore, immediate cleaning after assembly and after usage are highly recommended. The cleaning is done by flushing or rinsing all the impurities by using cleaning media such as:

- Strong compress air blast

- Sponge-like projectiles

- Cleaning liquids

Final Word

More? Please contact us at (65) 6298 3211 or enquiry@wahjooseng.com. Click here to check our hose collections or general hose installation guidelines.